LOCATION : HOME > News > Industry News

Zhongrui teaches you how to save more money, not to see

user:admin time:2018-11-20 view:1690

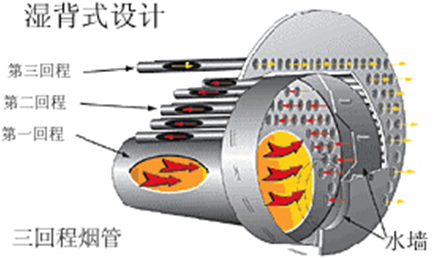

Zhongrui steam boiler in the convective heat exchange of the tobacco pipe area layout, abandoned the traditional two- and three-return "equal flow rate" design point of view, the use of "equal resistance" design new ideas to arrange convective heat transfer surface, in the furnace design The traditional design idea of determining the diameter of the furnace by the diameter of the flame has been broken, and the structure of the large corrugated furnace is adopted, the radiation heat transfer area is greatly improved, and the NOx emission is reduced. The threaded pipe technology is applied in the convective heat transfer pipe section, and the boiler efficiency reaches over 96.2%, which greatly improves the boiler efficiency. The smoke box adopts a double-sealed small smoke chamber structure to prevent smoke leakage, which is convenient for the user to repair. The heat preservation adopts aluminum silicate fiber felt, and the heat preservation effect is good. Since we have done a lot of work in combustion and heat transfer, we have adopted some new structures and new technologies, which have greatly reduced the size of the product, reduced the space occupied by the machine room, and reduced the weight.

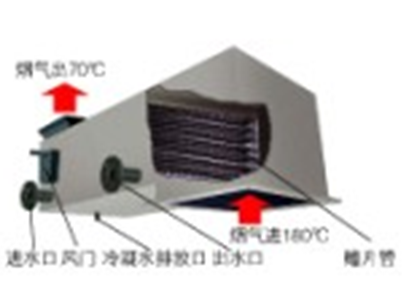

The flue gas condensation waste heat recovery device uses the lower temperature water or air to cool the flue gas to reduce the flue gas temperature, close to the heat exchange surface area, and the water vapor in the flue gas condenses, and at the same time realize the sensible heat release of the flue gas and the latent heat of steam condensation. Released, while the water or air in the heat exchanger absorbs heat and is heated to achieve heat recovery and improve boiler thermal efficiency.

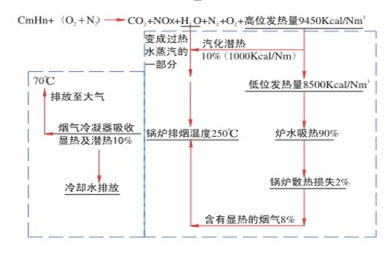

Increased boiler thermal efficiency: The theoretical flue gas production of 1NM3 gas combustion is about 10.3 NM3 (about 12.5KG). Taking the excess air ratio of 1.3 as an example, a flue gas of 14 NM3 (about 16.6 KG) is produced. Take the flue gas temperature 200 ° C to 70 ° C, release physical sensible heat about 1600KJ, water vapor condensation rate of 50%, release vaporization latent heat of about 1850 KJ, a total exotherm 3450 KJ, about 10% of the natural gas low heat. If 80% of the flue gas enters the heat recovery unit, the heat energy utilization rate can be increased by 8% or more, and the natural gas fuel can be saved by nearly 10%.

Separate layout, various installation forms, flexible and reliable.

As a hot surface, the spiral finned tube has high heat exchange efficiency, sufficient heating surface, and low resistance of the flue gas side system, which meets the requirements of ordinary burners.

Comparison of operating costs:

Compared with other types of boilers, horizontal steam boilers equipped with stainless steel blade flue gas condensers provide the same heat supply because of their high thermal efficiency, which is very economical. When comparing with a conventional horizontal steam boiler (smokeless energy saver), the energy saving of the entire system should be considered. The thermal efficiency of a horizontal steam boiler includes a condenser. The efficiency of a common horizontal steam boiler is 90%, and the gas consumption of a 600,000 kcal/h (commonly known as lt) boiler is:

600000/8500/90%=78(m3/h)

The horizontal steam boiler is installed in the tail of the boiler flue, which fully absorbs the heat loss of the flue gas. The system is simple and the exhaust gas temperature can be reduced to less than 100 °C. The air consumption of a horizontal steam boiler after installation of a 600,000-calorie stainless steel slab condenser is: 600000/8500/96%=73 (m3/h)

It consumes less gas (m3/h) than ordinary horizontal steam boilers, such as using 2400h per year to save gas:

5×2400=12000(m3)

If the gas price is 2.5 yuan / m3, the annual savings:

12000m3 × 2.5 yuan / m3 = 30,000 yuan.